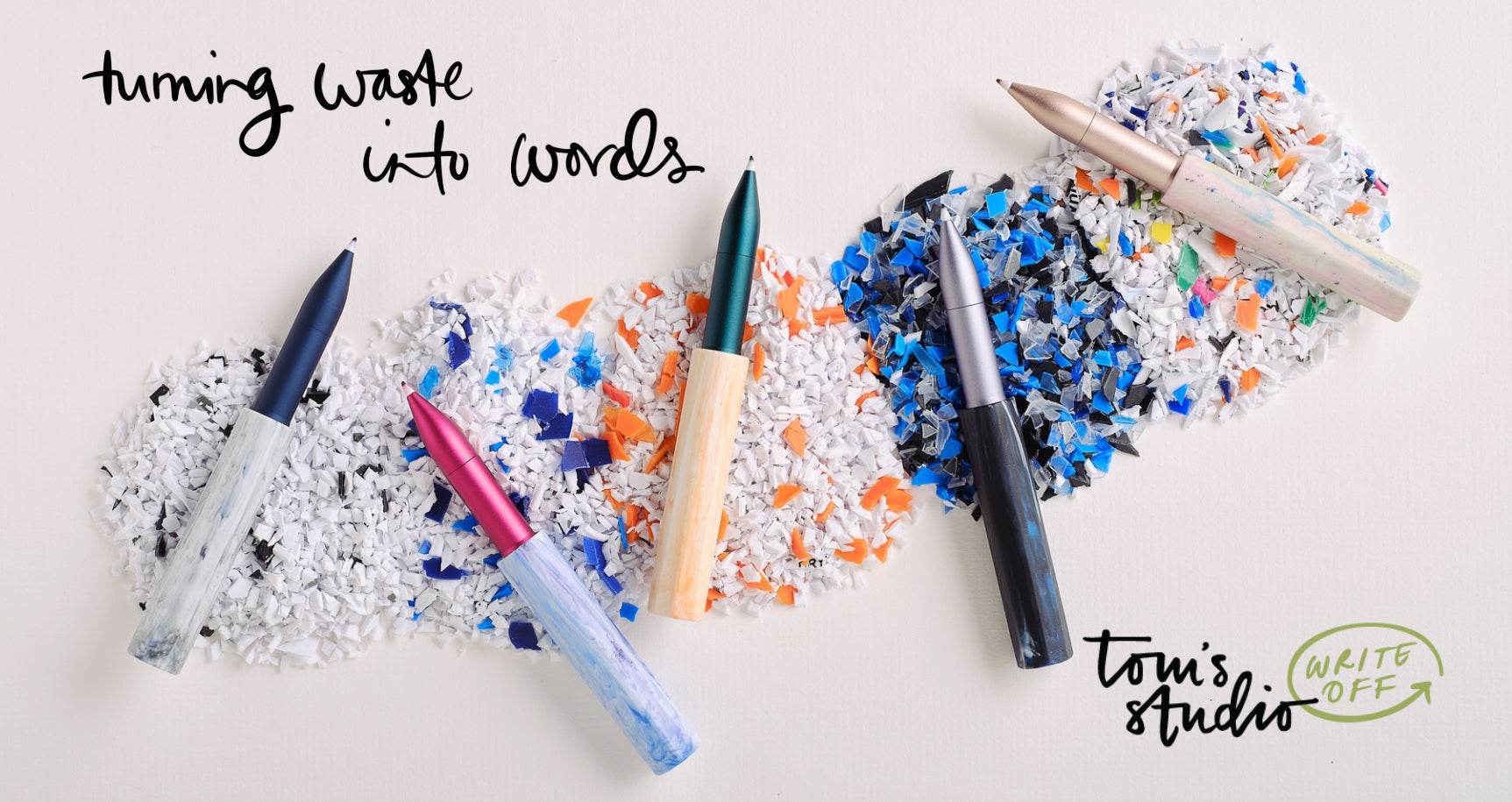

I'm always looking for ways to make creativity more thoughtful and intentional –without adding to the waste pile. That’s why I'm so excited to introduce our latest collaboration with Brothers Make, the brilliant duo turning discarded plastic into beautiful, functional objects.

From their UK-based workshop, brothers Matt and Jonny have made it their mission to rethink waste, transforming used plastics into new, responsibly made products. With their help, we’ve created the Wren – Write Off, a range of pen lids crafted from waste plastic, giving new purpose to materials that would otherwise be thrown away.

In this behind-the-scenes interview, we chat with the Brothers Make team about their journey, the process of turning plastic into something special, and what responsible making really means to them.

🎥 Watch the video below for a peek inside the process, and scroll down to read our full conversation with Brothers Make.

Can you tell us a bit about Brothers Make – how did it all begin?

We’ve told this story a few times, and honestly, the way we always put it is that it started as an excuse for us to hang out more. I’d just had my first kid, and he was about a year old when we realised we weren’t seeing each other as much. So, we decided to take on a little project together – renovating my garage.

Originally, the plan was for Johnny to teach me the drums (he’s been playing since he was seven). But apparently, I’m "unteachable" when it comes to drumming, so that plan didn’t last long. Instead, we just started making stuff together.

At first, it was just a fun thing we did in our spare time, but we got more and more into it. We both dropped down to four-day work weeks so we could spend one day a week on Brothers Make. Then that turned into two. And eventually, just over two years ago, we took the leap to go full-time.

What inspired you to start working with recycled plastics?

It was kind of an accident, to be honest. As a D&T teacher, I saw how much plastic schools throw away – just an absolutely mad amount. Whether it was offcuts from laser-cut projects or the sheer volume of single-use plastic from the canteen, it was everywhere.

Around the same time, I saw a YouTube video from a guy called Peter Brown. He’s not a plastics guy, but he did this one-off project where he melted milk bottle tops in an oven to make a mallet. I thought it was cool, so I went into school the next day and tried it myself. We still use that mallet in the workshop to this day!

Then, a group of A-level students asked me if we could make something out of recycled plastic. When I asked what, they said pens. At that point, I’d never turned a pen in my life, but I thought, why not? The first attempt came out… alright. Not amazing. But I brought one home, showed Johnny, and he said, "Let’s make a video about it." I wasn’t convinced, but we did it anyway.

That video – our guide to working with HDPE – blew up. It took us from 6,000 subscribers to 60,000 almost overnight. And from there, we got hooked on working with recycled plastics.

What’s been the most unexpected part of your journey so far?

The reach. You know, plastic waste is a global problem, but we’ve always taken a really local approach – our tagline is Think Global, Make Local. The idea is that if every town had a little workspace like ours, so much plastic could be reused instead of binned.

But what we didn’t expect was how many opportunities that would create. We’ve ended up travelling all over the world, setting up recycling workspaces and training people in how to process plastic waste. Last year, we went to Malaysia to teach the government how to recycle plastics. We’ve been to Gambia, where there’s literally no waste system at all, helping people turn their own plastic waste into usable materials. And just recently, we were in the Caribbean helping a jeweller set up a recycling workshop.

It’s mad how many people around the world want to be part of this, and it’s led to some incredible experiences.

The Collaboration

How did the idea for the Write Off range come about?

I actually met Tom at a market about three years ago. We got chatting, realised we had a really similar way of thinking about making things, and stayed in touch.

Tom had this idea for making pens out of old pens. It sounds obvious, but when you think about how much stationery waste is created – especially in schools – it makes total sense. I’ve seen it first-hand as a teacher. Kids go through pens so fast.

So Tom came to us and asked, "Do you reckon we could make a pen lid entirely out of recycled pens?" And honestly? We weren’t sure. But Tom’s one of those people who loves pushing the boundaries, and after years of working with injection moulding, we figured we’d give it a shot. It was a challenge, but we made it work. Now, every Wren pen lid is made from recycled pens, which is pretty cool.

Can you walk us through the process of turning plastic waste into a pen lid?

It starts with collecting plastic. Normally, we get post-consumer waste like milk bottle tops from schools, shampoo bottles from salons, and bleach containers from cleaning companies. We also take manufacturing offcuts that would otherwise end up in landfill.

Everything goes through a strict cleaning and sorting process. We check each piece by hand, scan it to confirm the plastic type, then separate it by colour before shredding it into tiny flakes.

For the Write Off range, instead of general post-consumer plastic, we exclusively use old pens from schools. That means fully disassembling them, sorting the different plastic types, and shredding the ones we can use. A lot of pens are made from tricky plastics like ABS and polycarbonate, which aren’t great for our process, but we look for polypropylene – the type found in whiteboard markers and Sharpie caps.

Then, the flakes are heated and injected into a mould using a hand-powered machine. Unlike commercial factories that use massive automated machines, we do it all manually. That makes it way more energy-efficient and lets us control every piece that comes out.

What were some of the biggest challenges in bringing this project to life?

The Wren pen lid is a really tricky shape. It’s much narrower than anything we’d worked on before, so we had to use a special (and expensive) manufacturing technique called EDM (Electrical Discharge Machining).

Another challenge was keeping the finish consistent. Recycled plastic can be unpredictable, but for a product like the Wren, every piece had to be perfect. Working with Tom’s Studio meant upping our game even further to meet their high standards.

What excites you most about this collaboration with Tom’s Studio?

The fact that it’s actually making a dent in a massive waste problem. Used pens are normally just chucked in the bin. Turning them into something new – not just something functional, but something really well made – is huge.

Responsibly Made & Thoughtfully Designed

In your experience, what’s the biggest misconception about working with recycled plastic?

That it’s lower quality. People assume it’s weak or inconsistent, but if you process it properly, it can be just as durable (if not better) than virgin plastic.

What role do you think small, independent makers have in rethinking how materials are used?

A huge role. We can take risks and try things that big manufacturers wouldn’t. We can be more experimental, more creative, and show people what’s actually possible with waste materials.

Do you have any advice for people looking to make more conscious choices in the materials they use?

Start small. See what waste streams exist around you and think about how they could be repurposed. And support businesses that are making sustainable choices – it makes a difference.